隨著科技的不斷進步,不銹鋼在機械製造行業中扮演著越來越重要的角色。不銹鋼具有耐腐蝕、易清潔和耐高溫等優點,因此被廣泛應用於各類機械設備的製造中。而在製程中,雷射切割技術成為了一項關鍵的工具,有效地提高了生產效率和加工精度。

未來,不銹鋼在機械製造中的應用將繼續擴大。隨著人們對品質要求的提高,對不銹鋼材料的需求也將不斷增加。同時,雷射切割技術將會更加普及和成熟,進一步提升機械加工的效率和精準度。這將有助於推動機械製造行業向更先進的方向發展。

Keywords: Stainless steel, machinery, laser cutting

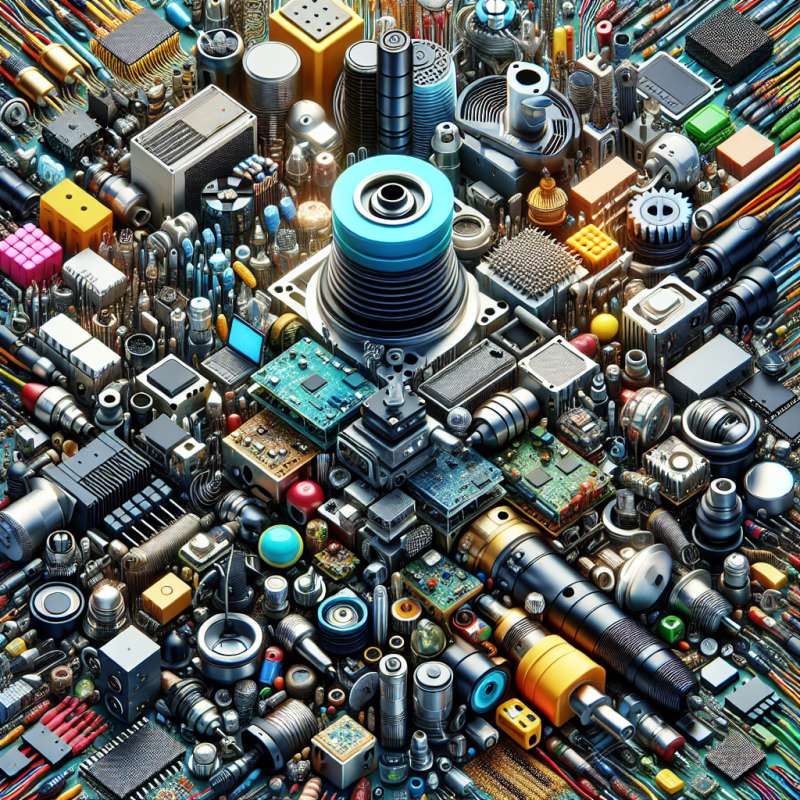

Title: The Application of Stainless Steel in Machinery Manufacturing and the Development Trend of Laser Cutting Technology

Article: With the continuous advancement of technology, stainless steel plays an increasingly important role in the machinery manufacturing industry. Stainless steel has advantages such as corrosion resistance, ease of cleaning, and high temperature resistance, making it widely used in the manufacturing of various types of mechanical equipment. In the manufacturing process, laser cutting technology has become a key tool that effectively improves production efficiency and processing accuracy.

In the future, the application of stainless steel in machinery manufacturing will continue to expand. With the increasing demand for quality, the demand for stainless steel materials will also continue to grow. At the same time, laser cutting technology will become more popular and mature, further enhancing the efficiency and precision of mechanical processing. This will help drive the machinery manufacturing industry towards a more advanced direction.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)