模具製造是製造業中的重要環節,而金屬加工則是模具製造中不可或缺的步驟之一。在製造過程中,CNC加工技術被廣泛應用,能夠提供高精度和高耐用性的零件製造。另外,表面處理也是模具製造中的重要一環,能夠增加產品的外觀質感和耐用性。

模具製造中,首要考慮的是金屬加工材料的選擇,以確保最終產品符合設計要求。而在製造過程中,包括CNC加工、熱處理和表面處理等步驟都至關重要。優秀的模具設備和制模技術,能夠提高金屬成型的效率和質量,保證產品的一致性。

模具製造產業是一個充滿挑戰和機遇的行業,需要不斷學習和創新。精密加工和模具維護是保證模具生產效率和品質的重要環節。制定模具標準,能夠提高生產效率和降低生產成本,讓模具製造更具競爭力。

Translation:

Keywords: Mold Manufacturing, Metal Processing, CNC Machining, Surface Treatment

Title: Mold Manufacturing and Metal Processing Technology

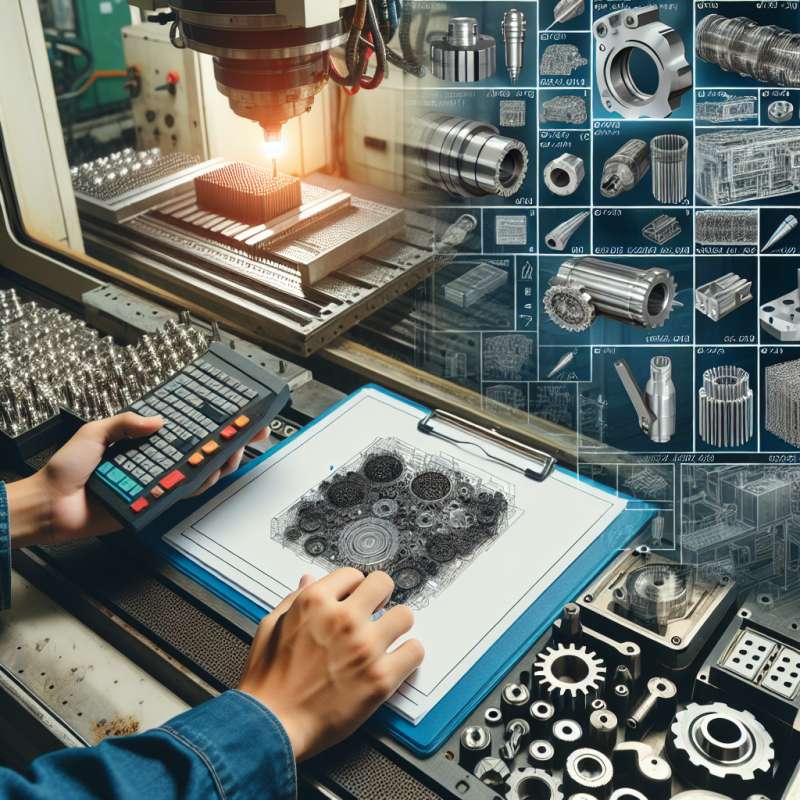

Article: Mold manufacturing is an essential part of the manufacturing industry, and metal processing is an indispensable step in mold manufacturing. In the manufacturing process, CNC machining technology is widely used, providing high precision and durable parts manufacturing. In addition, surface treatment is also an important aspect of mold manufacturing, enhancing the appearance and durability of the products.

In mold manufacturing, the choice of metal processing materials is crucial to ensure that the final product meets design requirements. In the manufacturing process, steps including CNC machining, heat treatment, and surface treatment are all critical. Excellent mold equipment and molding technology can improve the efficiency and quality of metal forming, ensuring product consistency.

The mold manufacturing industry is a challenging yet promising industry that requires continuous learning and innovation. Precision machining and mold maintenance are important for ensuring manufacturing efficiency and quality. Establishing mold standards can improve production efficiency and reduce production costs, making mold manufacturing more competitive.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)