近年來,金屬加工產業在全球市場上扮演著重要的角色。隨著科技的進步,CNC技術已經成為金屬加工中不可或缺的工具之一。CNC(Computer Numerical Control)技術的應用,讓金屬加工變得更加精準和高效率。

除了CNC技術,汽車產業的發展也密切關係著金屬加工產業。隨著電動車的普及和需求增加,金屬加工廠商也需跟上趨勢,提供更高品質的零件。這也帶動了電鍍技術的需求,以增加產品的耐用性和美觀度。

金屬刀具製造是金屬加工產業中一環相當重要的環節。優質的金屬刀具不僅可以提高加工效率,還能保證產品的品質。因此,金屬刀具製造商需要與金屬加工廠商緊密合作,開發出更先進的刀具。

總括而言,金屬加工產業的未來趨勢是向智能化和高效率發展。透過CNC技術、汽車產業和電鍍技術的發展,金屬加工廠商將能夠提供更高品質的產品,並在市場上保持競爭力。

Keywords: CNC, automotive, processing, electroplating, metal tool manufacturing

Title: The Future Trends of Metal Processing Industry

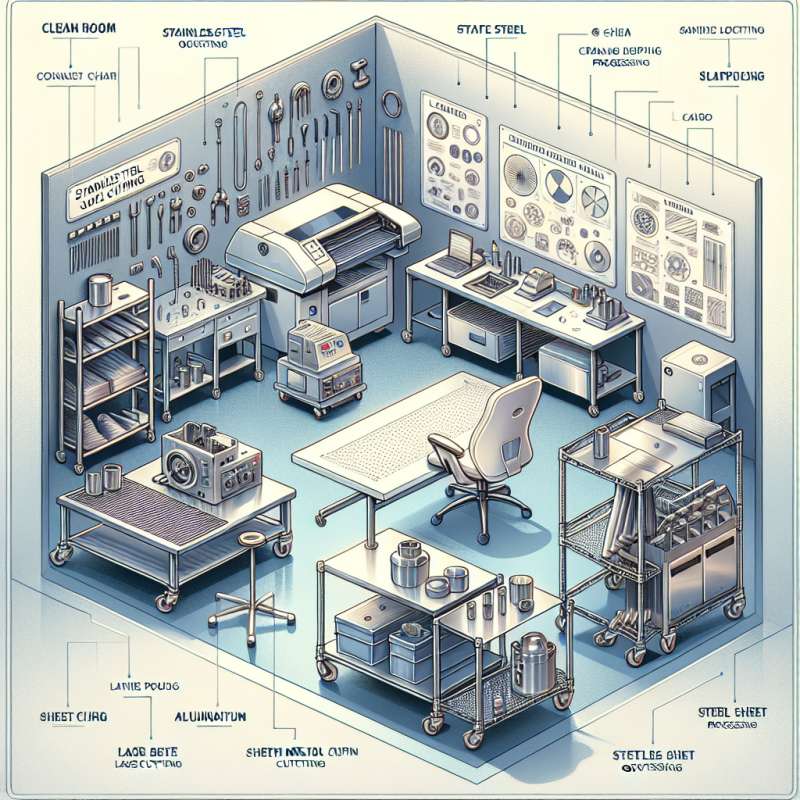

Article: In recent years, the metal processing industry plays a crucial role in the global market. With the advancement of technology, CNC technology has become an indispensable tool in metal processing. The application of CNC (Computer Numerical Control) technology has made metal processing more precise and efficient.

In addition to CNC technology, the development of the automotive industry is closely related to the metal processing industry. With the popularity and increasing demand for electric vehicles, metal processing manufacturers need to keep up with the trend by providing higher-quality parts. This has also driven the demand for electroplating technology to increase the durability and aesthetics of products.

Metal tool manufacturing is an essential part of the metal processing industry. High-quality metal tools not only improve processing efficiency but also ensure product quality. Therefore, metal tool manufacturers need to work closely with metal processing manufacturers to develop more advanced tools.

In summary, the future trend of the metal processing industry is towards intelligence and efficiency. Through the development of CNC technology, the automotive industry, and electroplating technology, metal processing manufacturers will be able to provide higher-quality products and maintain competitiveness in the market.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)