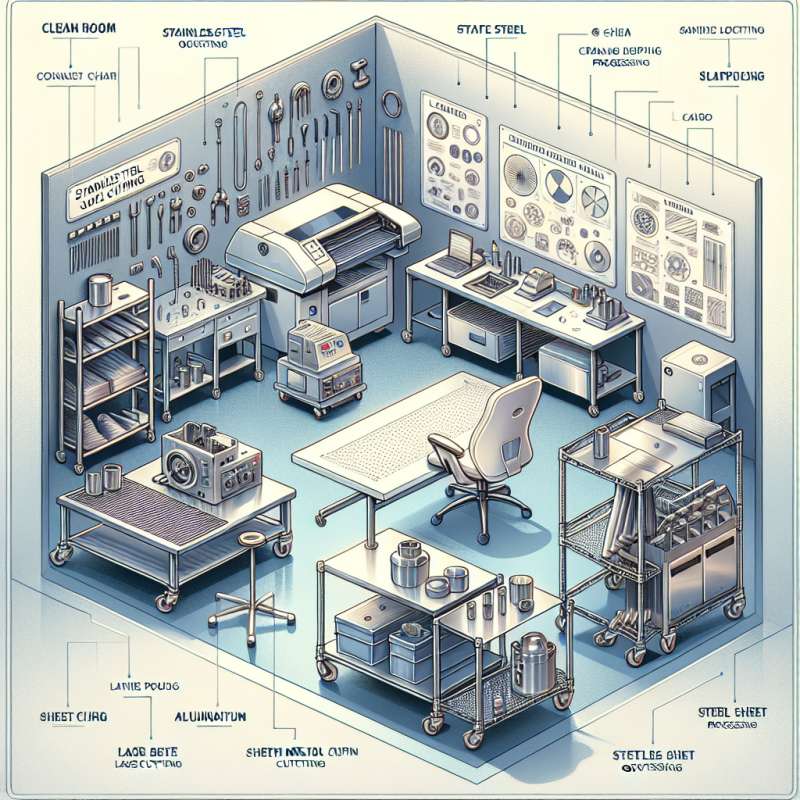

金屬刀具是日常生活中常見的工具,從廚房刀具到工業用途的鋸片都是由金屬製成。在製造金屬刀具的過程中,制造工廠需要嚴謹的制造工藝和精密的手工具。

首先,製造金屬刀具的過程始於選擇合適的金屬材料。常見的金屬材料包括不銹鋼、碳鋼和高速鋼等。這些金屬材料因其硬度和耐用性而適用於製造不同類型的刀具。一旦選擇了適合的金屬材料,製造工廠便會將其送入製造機器進行加工。

在製造過程中,金屬刀具通常需要經過多次的加工和熱處理,以確保刀具的硬度和耐用性。製造工廠會使用各種手工工具和機器來削下,打磨和熱處理金屬刀具,使其達到所需的形狀和性能。

最後,製造工廠會將金屬刀具進行檢驗和包裝,以確保刀具符合標準並且能夠安全使用。製造金屬刀具是一個複雜的過程,需要制造工廠的豐富經驗和技術。只有通過精密的制造工藝和高品質的手工具,才能生產出優質的金屬刀具。

In English:

Keywords: Metal tools, Manufacturing, Manufacturing factory

Title: The manufacturing process of metal tools

Article: Metal tools are common tools in daily life, from kitchen knives to industrial saw blades are made of metal. In the process of manufacturing metal tools, manufacturing factories require rigorous manufacturing processes and precise hand tools.

Firstly, the process of manufacturing metal tools begins with selecting the appropriate metal materials. Common metal materials include stainless steel, carbon steel, and high-speed steel, etc. These metal materials are suitable for making different types of tools due to their hardness and durability. Once the suitable metal material is chosen, the manufacturing factory will send it to the manufacturing machine for processing.

During the manufacturing process, metal tools usually need to undergo multiple processes of machining and heat treatment to ensure the hardness and durability of the tools. Manufacturing factories will use various hand tools and machines to cut, grind, and heat-treat metal tools to achieve the desired shape and performance.

Lastly, the manufacturing factory will inspect and package the metal tools, to ensure that the tools meet the standards and can be used safely. Manufacturing metal tools is a complex process that requires rich experience and technology from the manufacturing factory. Only through precise manufacturing processes and high-quality hand tools can high-quality metal tools be produced.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)