金屬模具製造是製造產業中非常重要的一環,因為模具的品質會直接影響到最終產品的品質。要製造高精度高耐用性的零件,必須選擇適合的金屬加工材料,並透過精密的加工技術來製造模具。

在金屬模具製造的過程中,CNC加工是一個關鍵技術。透過CNC加工,可以實現高精度的加工,確保模具的準確度和一致性。此外,經過熱處理和表面處理的模具不僅能提升硬度和耐磨性,還能延長模具的使用壽命。

然而,模具維護同樣重要。定期的保養和保持模具的標準是確保其長期高效運作的關鍵。只有在模具使用過程中嚴格遵循維護標準,才能確保模具的品質和穩定性。

在現代製造業中,金屬模具製造不僅是一個技術活,更是一門藝術。只有通過合理的設計、精密的加工和有效的維護,才能製造出優質的金屬模具,為產品的生產提供質量保證。

Keywords: Metal Mold Manufacturing, CNC Machining, Heat Treatment, Surface Treatment, Mold Maintenance

Title: Design and Maintenance of High-Quality Metal Molds

Article:

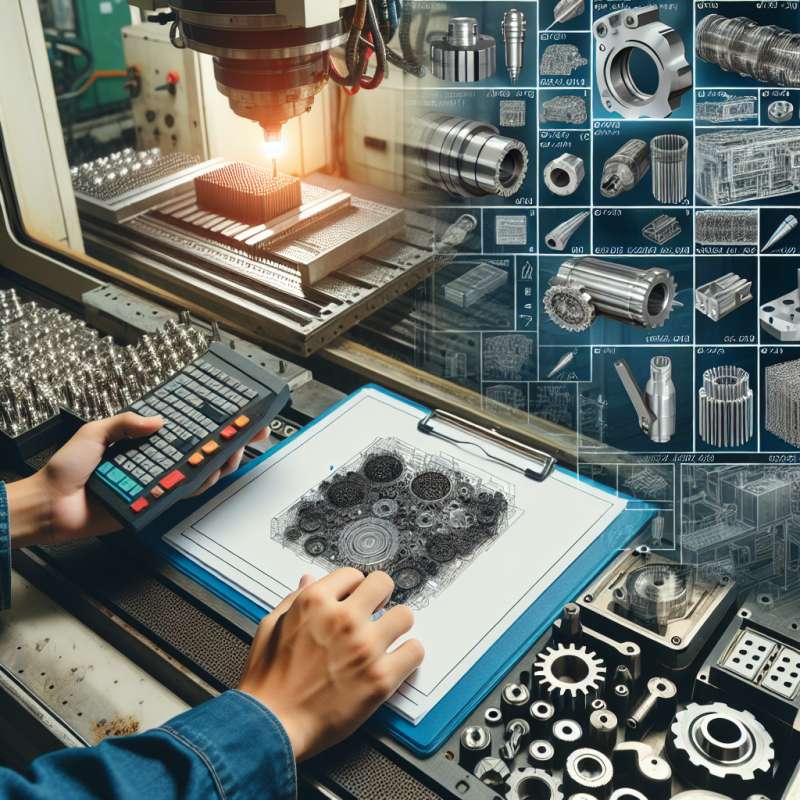

Metal mold manufacturing is a crucial part of the manufacturing industry, as the quality of molds directly impacts the quality of the final products. To produce high-precision and durable parts, it is essential to choose the right metal machining materials and utilize precise machining techniques in mold manufacturing.

In the process of metal mold manufacturing, CNC machining plays a vital role. CNC machining enables high-precision processing, ensuring the accuracy and consistency of molds. Additionally, molds that have undergone heat treatment and surface treatment not only enhance hardness and wear resistance but also prolong the mold's lifespan.

However, mold maintenance is also critical. Regular maintenance and adherence to maintenance standards are key to ensuring the long-term efficient operation of molds. Only by strictly following maintenance standards during mold usage can the quality and stability of molds be guaranteed.

In modern manufacturing industry, metal mold manufacturing is not just a technical activity but also an art. Only through proper design, precise machining, and effective maintenance can high-quality metal molds be produced to provide quality assurance for product manufacturing.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)