金屬刀具是一種常見的手工具,廣泛應用於家庭、工業和農業等領域。在制造金屬刀具的過程中,首先需要選擇適合的材料,通常是一種高品質的鋼材。然後將鋼材切割成符合需求的形狀,這個步驟需要使用專業的金屬切割機械。接下來,將金屬刀具的刃研磨成鋒利的形狀,這需要高精度的磨刀工具。最後,金屬刀具的表面會進行處理,例如噴漆或電鍍,以增加耐用性和美觀性。

金屬刀具的製造是一個複雜的過程,需要先進的製造工藝和設備。許多公司專門從事金屬刀具的制造,他們擁有先進的制造工廠和技術人員,能夠生產出高品質的金屬刀具產品。這些金屬刀具不僅在市場上有著良好的口碑,而且在各行各業都有廣泛的應用。

Key words: Metal cutting tools, manufacturing, manufacturing factory

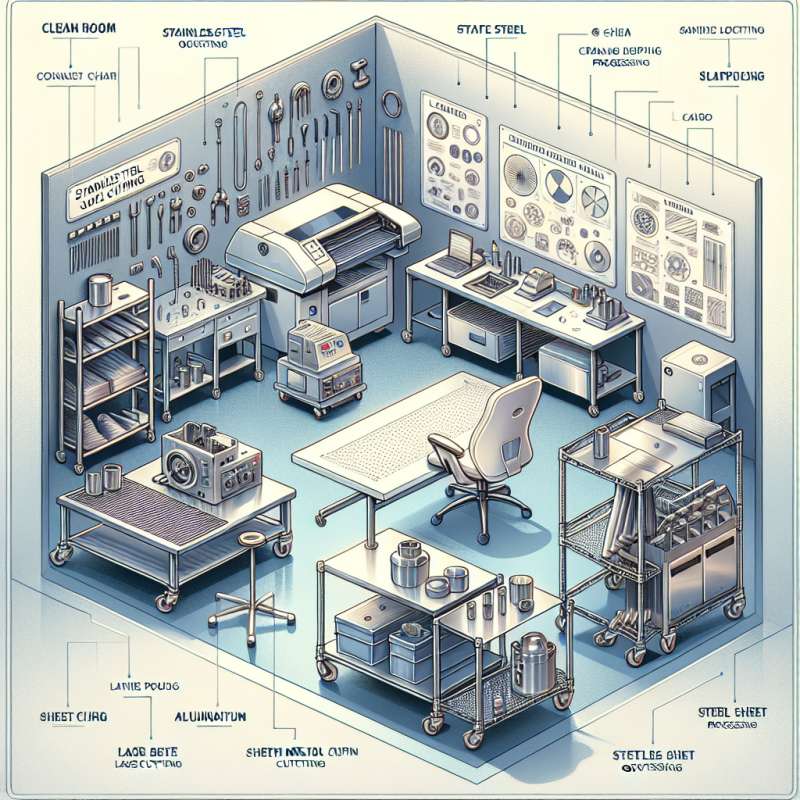

Title: The manufacturing process of metal cutting tools

Article: Metal cutting tools are common hand tools widely used in household, industrial, and agricultural fields. In the process of manufacturing metal cutting tools, the first step is to select suitable materials, usually high-quality steel. Then the steel is cut into the desired shape using specialized metal cutting machinery. Next, the blade of the metal cutting tool is sharpened to a sharp edge, requiring precision sharpening tools. Finally, the surface of the metal cutting tool is treated, such as painting or plating, to increase durability and aesthetics.

The manufacturing of metal cutting tools is a complex process that requires advanced manufacturing processes and equipment. Many companies specialize in the manufacturing of metal cutting tools, having advanced manufacturing factories and technical personnel that can produce high-quality metal cutting tool products. These metal cutting tools not only have a good reputation in the market but also have a wide range of applications in various industries.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)