金屬刀具一直以來都是人們在日常生活中不可或缺的工具之一。為了製造出高品質的金屬刀具,制造商們必須精益求精地運用制造工藝。

首先,金屬刀具的製造從設計開始。設計師考慮到刀具的用途和外觀,並利用電腦軟件來製作設計圖。接下來,制造商選擇合適的金屬材料,通常是不銹鋼或碳鋼。這些材料被送往制造工廠進行加工。

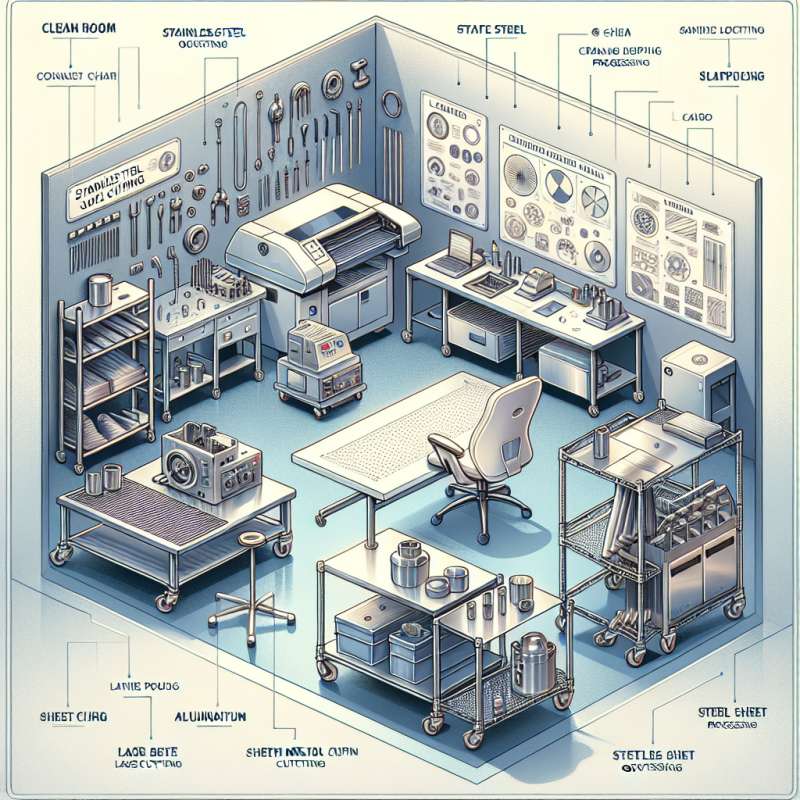

在制造工廠,製造工人們使用各種手工具和機器來加工金屬材料。他們可能會使用切割工具來切割金屬,然後使用研磨工具來磨削刀具的刀刃。工藝師可能還會應用熱處理技術來增加刀具的硬度和耐用性。

最後,金屬刀具經過一系列測試,確保其品質符合標準。這些測試可能包括硬度測試和使用壽命測試。一旦金屬刀具通過了所有測試,它們就會被包裝和送往市場出售。

金屬刀具的製造工藝需要精細的技術和專業知識。這些製造商通過不斷改進工藝和技術,來生產出高品質、耐用的金屬刀具,以滿足消費者的需求。

Keywords: metal cutting tools, manufacturing, manufacturing process

Title: The Manufacturing Process of Metal Cutting Tools

Article: Metal cutting tools have always been essential tools in people's daily lives. In order to produce high-quality metal cutting tools, manufacturers must continuously improve the manufacturing process.

Firstly, the manufacturing of metal cutting tools starts with design. Designers consider the tool's function and appearance and create design drawings using computer software. Next, manufacturers select appropriate metal materials, usually stainless steel or carbon steel. These materials are then sent to manufacturing plants for processing.

In the manufacturing plant, skilled workers use a variety of hand tools and machines to process the metal materials. They may use cutting tools to cut the metal, and then use grinding tools to sharpen the blade of the cutting tool. Craftsmen may also apply heat treatment techniques to increase the hardness and durability of the tool.

Finally, the metal cutting tools undergo a series of tests to ensure their quality meets standards. These tests may include hardness testing and durability testing. Once the metal cutting tools pass all tests, they are packaged and sent to the market for sale.

The manufacturing process of metal cutting tools requires precision techniques and specialized knowledge. These manufacturers continuously improve their processes and techniques to produce high-quality, durable metal cutting tools to meet consumer needs.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)