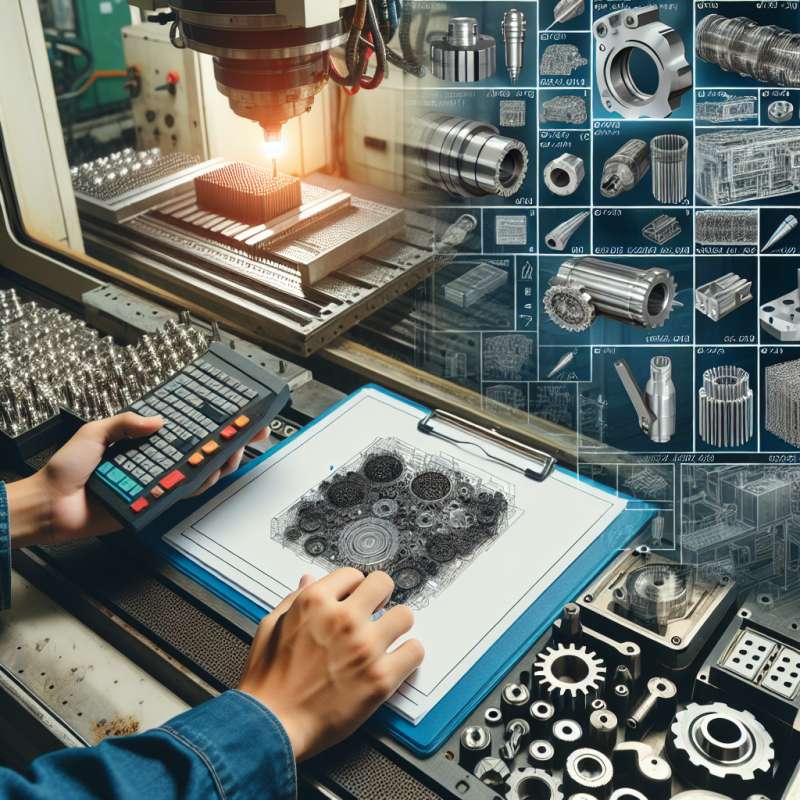

金屬模具製造是製造業中一個相當重要的環節,尤其對於生產高精度、高耐用性零件來說更是關鍵。製造金屬模具時,首先需要根據產品要求選擇適合的金屬加工材料,再依據零件要求進行模具設計,包括CNC加工、熱處理和表面處理等工序。

在金屬模具製造中,CNC加工是一個常見的工序,能夠提高生產效率和加工精度。此外,熱處理和表面處理可以增加模具的耐用性和使用壽命。模具設備也是十分重要的一環,適合的設備能夠提高模具生產效率和品質。

金屬模具製造通常被視為模具產業的一部分,而模具產業更是製造業中不可或缺的一個領域。精密加工和制模技術對於金屬模具製造至關重要,能夠確保模具的精度和質量,同時也需要進行金屬成型和模具維護等工作,以確保模具能長期保持高品質的生產效能。

金屬模具製造是製造業中不可或缺的一個環節,精準的製程和適當的技術應用能夠確保產品的品質和生產效率,對於整個產業鏈有著重要的影響。

---

Keywords: metal mold manufacturing, mold production, CNC machining, mold equipment

Title: The Importance and Process Analysis of Metal Mold Manufacturing

Article: Metal mold manufacturing is a crucial aspect in the manufacturing industry, especially for producing high-precision and durable components. When manufacturing metal molds, it is essential to choose suitable metal processing materials according to product requirements, followed by mold design processes such as CNC machining, heat treatment, and surface treatment.

In metal mold manufacturing, CNC machining is a common process that can enhance production efficiency and accuracy. Additionally, heat treatment and surface treatment can improve the durability and lifespan of molds. Mold equipment is also vital as suitable equipment can enhance mold production efficiency and quality.

Metal mold manufacturing is often seen as part of the mold industry, which is an indispensable sector in the manufacturing industry. Precision machining and mold-making technology are crucial for metal mold manufacturing to ensure the accuracy and quality of molds. Furthermore, metal forming and mold maintenance are essential tasks to guarantee long-term high-quality production performance of molds.

Metal mold manufacturing plays a crucial role in the manufacturing industry, and precise processes and appropriate technological applications can ensure product quality and production efficiency, significantly impacting the entire industry chain.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)