金屬刀具一直以來都是人們在日常生活和工作中不可或缺的工具之一。它們可以用來切割、削減、雕刻和修理各種材料,因此在各行各業都有廣泛的應用。

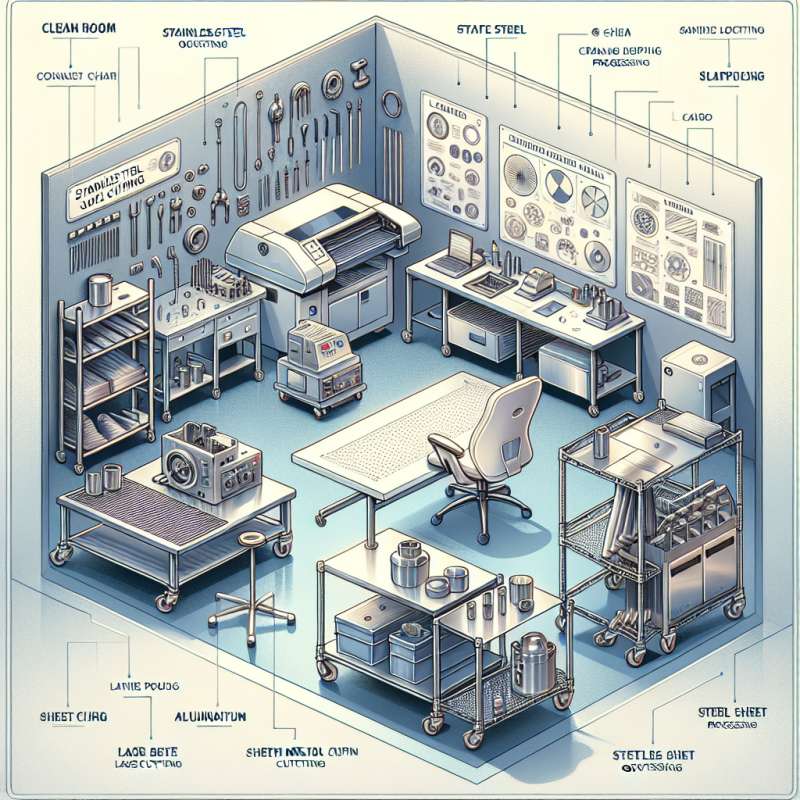

金屬刀具的製造工藝非常複雜,需要經過多道工序才能完成。首先,製造商需要選擇適合的金屬材料,如不銹鋼、碳鋼或高速鋼,然後將其加熱至適當的溫度。接著,工匠們使用各種手工具和機器來將金屬材料塑造成刀具的形狀,並進行精密的研磨和拋光工藝,以確保刀具的切割效果和耐用性。

在製造過程中,工匠們需要密切注意每一個細節,以確保刀具的質量符合標準。他們可能會使用顯微鏡來檢查刀刃的鋒利度,或者進行硬度測試以確保刀具可以長時間保持切割效果。

最後,製造完成的金屬刀具會被送往各個行業的使用者手中,幫助他們更高效地完成工作。無論是廚房裡的廚師、工廠裡的工人還是藝術家,金屬刀具都是他們的得力助手。

金屬刀具的製造工藝是一門古老而精湛的技藝,通過不斷的創新和改進,製造商們能夠生產出更加優質和高效的刀具,滿足人們不斷增長的需求。

Keywords: Metal knives, Hand tools, Manufacturing process

Title: The Manufacturing Process of Metal Knives

Article: Metal knives have always been indispensable tools in people's daily lives and work. They can be used to cut, trim, carve, and repair various materials, making them widely used in various industries.

The manufacturing process of metal knives is very complex and requires multiple steps to complete. Firstly, manufacturers need to choose suitable metal materials such as stainless steel, carbon steel, or high-speed steel, and then heat them to the appropriate temperature. Then, craftsmen use various hand tools and machines to shape the metal material into the shape of the knife, and carry out precise grinding and polishing processes to ensure the cutting effect and durability of the knife.

During the manufacturing process, craftsmen need to pay close attention to every detail to ensure the quality of the knife meets the standards. They may use a microscope to inspect the sharpness of the blade or conduct hardness tests to ensure that the knife can maintain its cutting effect for a long time.

Finally, the finished metal knives are sent to users in various industries to help them work more efficiently. Whether it's chefs in the kitchen, workers in factories, or artists, metal knives are their reliable assistants.

The manufacturing process of metal knives is an ancient and exquisite skill. Through continuous innovation and improvement, manufacturers can produce higher quality and more efficient knives to meet people's growing needs.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)