在製造業中,塑料成形、鍛造和表面處理是非常重要的關鍵技術。塑料成形是一種將熔融的塑料注入模具,然後冷卻成形的過程,常用於製造各種塑料製品。鍛造則是將金屬加熱至高溫後進行塑形,通常用於製造強度高的金屬製品。而表面處理則是通過不同的方法對產品表面進行處理,以提高其外觀和性能。

這些技術在製造業中扮演著重要的角色。塑料成形可以製造出各種形狀和大小的塑料製品,廣泛應用於汽車、家電、玩具等行業。鍛造則可以製造出高強度的金屬零件,常見於航空、汽車、機械等領域。而表面處理則可以提高產品的耐腐蝕性、耐磨性和美觀度,使產品更具市場競爭力。

製造業中的塑料成形、鍛造和表面處理技術不僅需要先進的設備和工藝,還需要專業的技術人才來操作和管理。只有不斷創新和提高技術水平,製造業才能在激烈的市場競爭中立於不敗之地。

Keywords: Plastic molding, Forging, Surface treatment

Title: Key Technologies in Manufacturing Industry

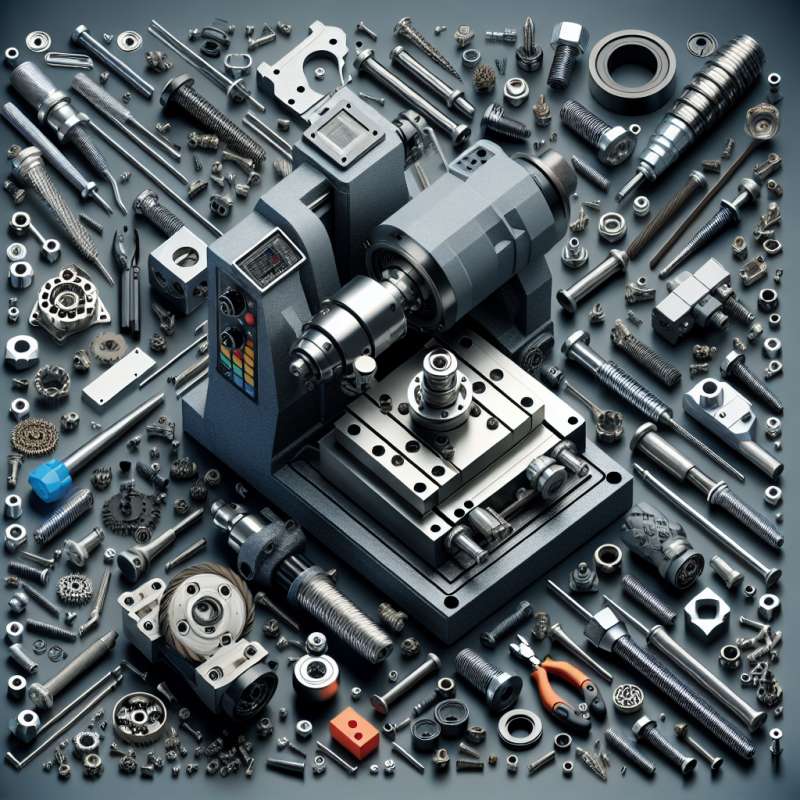

Article: In the manufacturing industry, plastic molding, forging, and surface treatment are crucial key technologies. Plastic molding is a process of injecting molten plastic into a mold and then cooling it to form various plastic products. It is commonly used in the production of a wide range of plastic products. Forging, on the other hand, involves shaping metal by heating it to high temperatures, typically used to manufacture high-strength metal products. Surface treatment, meanwhile, involves treating the surface of products through various methods to enhance their appearance and performance.

These technologies play vital roles in the manufacturing industry. Plastic molding can produce plastic products of various shapes and sizes, widely used in industries such as automotive, appliances, and toys. Forging can create high-strength metal parts commonly found in aerospace, automotive, and machinery sectors. Surface treatment can improve product corrosion resistance, wear resistance, and aesthetics, making products more competitive in the market.

The plastic molding, forging, and surface treatment technologies in the manufacturing industry require advanced equipment, processes, and skilled professionals to operate and manage them. Only through continuous innovation and improvement in technological capabilities can the manufacturing industry stay competitive in the market.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)