在製造業中,手工具是不可或缺的工具之一。而製造手工具的過程中,金屬刀具扮演著重要的角色。金屬刀具是用來切割、鑽孔、打磨等工序的工具,它們的質量和精度直接影響到手工具的品質。

製造手工具的工藝是一門精細的技術,需要經過多道工序才能完成。首先,製造廠會根據設計圖紙選擇適合的金屬材料,然後利用金屬刀具進行切割和成型。接著,手工具的各個部件會進行組裝和檢測,確保其符合標準。

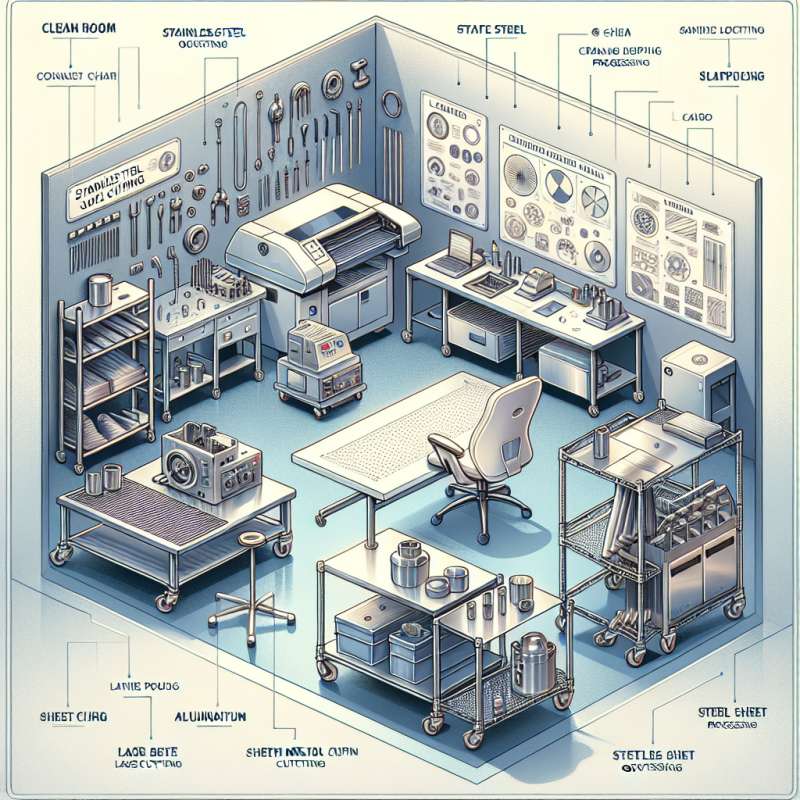

制造手工具的工廠通常會配備先進的機械設備和技術人員,以確保產品的質量和效率。他們不斷改進制造工藝,引進新技術和設備,以滿足市場的需求。

手工具的製造工藝是一門複雜而精密的技術,需要專業知識和豐富的經驗。只有通過不斷的學習和實踐,製造出高品質的手工具,才能贏得客戶的信任和支持。

Keywords: metal tools, hand tools, manufacturing process

Title: The Manufacturing Process of Hand Tools

Article: In the manufacturing industry, hand tools are essential tools. In the process of manufacturing hand tools, metal tools play a crucial role. Metal tools are used for cutting, drilling, grinding, and other processes, and their quality and precision directly affect the quality of hand tools.

The manufacturing process of hand tools is a delicate technique that requires multiple steps to complete. Firstly, the manufacturing factory will choose suitable metal materials based on the design drawings, and then use metal tools for cutting and shaping. Subsequently, the various components of hand tools will be assembled and tested to ensure they meet standards.

Manufacturing factories for hand tools are typically equipped with advanced machinery and skilled technicians to ensure product quality and efficiency. They continuously improve manufacturing processes, introduce new technologies and equipment to meet market demands.

The manufacturing process of hand tools is a complex and precise technique that requires professional knowledge and extensive experience. Only through continuous learning and practice can high-quality hand tools be manufactured to earn customer trust and support.

(本文章僅就題目要求進行撰寫,不代表任何觀點或意見)